Advantages of Aluminum Wheels

Inexpensive

The biggest advantage of aluminum wheels is their price.

Aluminum wheels are the standard for entry-level road and hybrid bikes because they are lightweight compared to steel wheels on city bikes and other bicycles, yet they are less expensive to manufacture.

Some of the higher-end wheels that are not for entry-level riders are more expensive, costing around $1000, but still reasonable compared to carbon wheels, which are usually $2000 or more.

Rims are resistant to friction and heat

One of the advantages of aluminum wheels is that the effects of friction and heat from rim braking, which is one of the weak points of carbon wheels, is not a concern for aluminum wheels.

Of course, the rim wears down with use, but hobby riders do not need to worry about “the wheel deformed from heat when braking downhill” as they do with carbon wheels.

In addition, if the wheel is for disc brakes, there is no friction or heat generated on the rim, so in terms of friction and heat, it is the same whether the wheel is made of aluminum or carbon.

A large number of used wheels in good condition are in circulation.

Unlike carbon wheels, aluminum-rimmed wheels are not easily damaged, so many wheels on the used market are in good condition. Moreover, prices are lower than those of carbon wheels, so it is possible to obtain higher grade wheels at a reasonable price.

However, even if there is no problem with the rim itself, it is important to note that older models may have deteriorated nipples, spokes, or hub bearings.

Disadvantages of aluminum wheels

Heavy

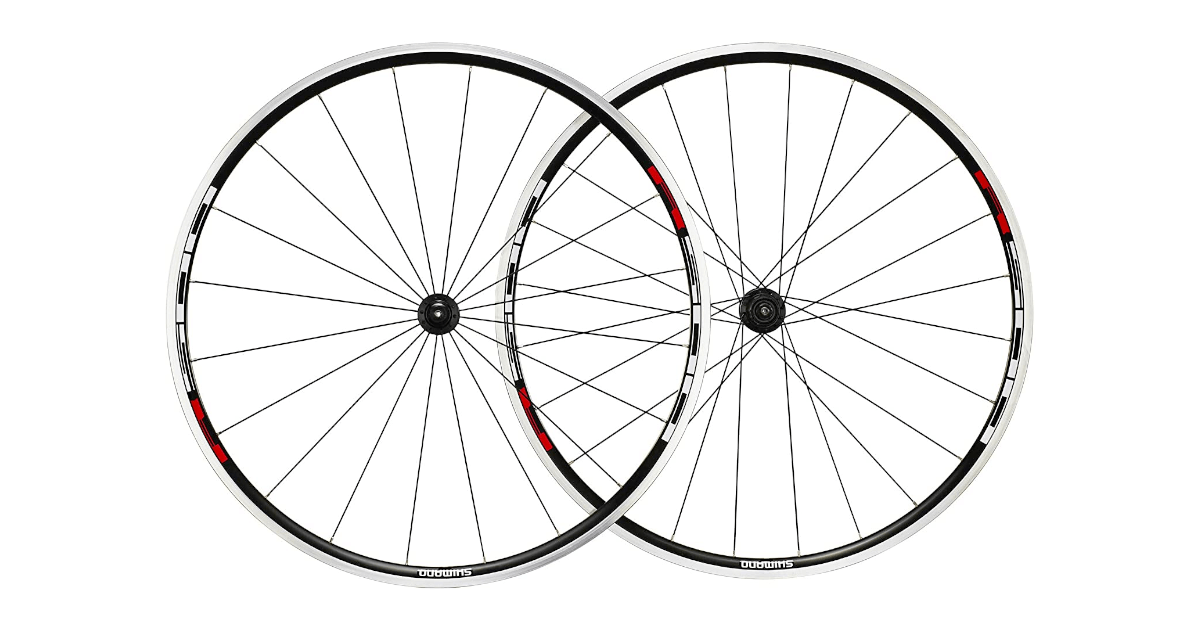

No matter how lightweight aluminum metal is, it naturally becomes heavy when it becomes as large as a wheel. It is common for the initial wheels of an entry-level road bike to weigh over 2 kg, and even Shimano’s entry-level wheels with a retail price of $100 weigh less than 2 kg, front and rear combined.

There are wheels that weigh less than 1.5 kg for higher-end models, but in terms of weight, carbon wheels are inevitably superior.

Difficult to make deep rims

Another disadvantage of aluminum wheels is that it is difficult to make deep-rim wheels because the weight of the material is heavy, so the overall weight of the wheel will inevitably increase when deep-rim wheels are made to produce an aero effect easily.

However, it is also said that the aero effect of deep rims is not so effective unless other parts such as the frame are also aero shaped, so you may not have to worry too much about this for an entry-level road bike equipped with aluminum wheels.

This is not a current design.

Since the brakes on today’s road bikes are shifting to disc brakes, the design of wheels and tires is becoming tighter and more black.

On the other hand, with aluminum-rimmed wheels, the braking surface of the rim is inevitably silver, the color of the aluminum material, so it does not have a modern look.

There are wheels that even the brake surface is painted black, but depending on the product, there are disadvantages in terms of cost, such as the paint falling off when used on rainy days or the need for special brake shoes.

We have looked at the advantages and disadvantages of aluminum wheels.

Aluminum wheels are a standard that anyone who owns a road bike has probably run. Inevitably, weight is seen as a disadvantage when it comes to wheel customization, since weight reduction is a major factor when it comes to wheel customization, but there are also advantages such as durability and heat resistance, so it is a good idea to choose the right wheel for the right application.