Shimano Chain Compatibility for Road, MTB, and Hybrid Bikes

An overview of Shimano chain compatibility across road bikes, mountain bikes, and hybrid bikes. Includes guidance on how to choose the right chain for your drivetrain.

Posted at: Feb 13, 2023

A torque wrench is a useful tool to have if you want to properly maintain your road bike or MTB. The following is a summary of what a torque wrench is and the advantages and disadvantages of torque management.

Table of contents

Sponsored Link

The word “torque” is often heard in road bike and MTB maintenance. Torque is “torsional strength” and refers to the amount of force used to tighten a bolt or screw.

The unit of torque is expressed in N-m (Newton meters), and sports bicycle parts and manuals specify the tightening torque for installation.

A torque wrench is a wrench that can manage torque.

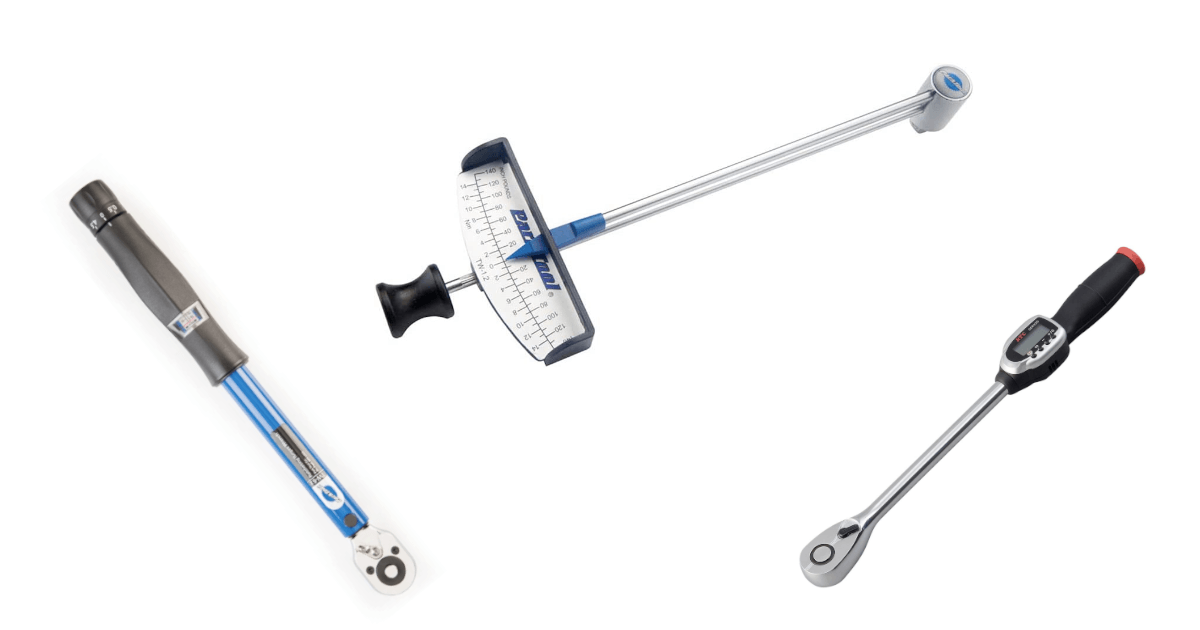

There are many types of torque wrenches. In terms of function, there are three major differences.

The first major difference is the behavior when the specified torque is reached. Torque wrenches that do not have a idling function and simply measure are inexpensive, but depending on the addition or subtraction, there is a possibility that the torque may be tightened beyond the specified torque.

In addition, some torque wrenches allow setting of torque values, while others do not. Most torque wrenches for maintenance can change the torque value in detail, but many portable torque wrenches are the type that idles at the torque set in the product, such as 5 nm. It is small and convenient for carrying, but it is not capable of fine torque management.

Finally, there is a difference in measurement method. Most torque wrenches set the torque value by analog, but some models display the current torque value digitally and inform you with a beep sound when the set torque value is reached.

Which torque wrench to choose depends on the application and the accuracy of maintenance you are looking for, so you will have to consult with your budget to choose the best one.

A wrench with a similar name is called a “torque wrench,” but they are completely different.

As explained earlier, the “torque” in a torque wrench refers to the strength of tightening, while the “Torx” in a Torx wrench is a standard for hexagonal star-shaped screw heads developed by the American company Textron Kamker.

Torx is characterized by the star-shaped screw head and is called “star-shaped screw.

Therefore, a Torx wrench cannot be used to control the tightening torque on a road bike or MTB.

On the other hand, if you have a torque wrench with an interchangeable pit, you can manage the tightening torque of Torx screws by preparing a Torx pit.

The advantage of torque management is the ability to optimize the tightening of parts.

Each part has an optimum torque value recommended by the manufacturer, and this value is set to “prevent the part from coming off without breaking the part,” thus increasing the reliability of the part’s assembly.

In addition, carbon products such as carbon frames, carbon seat posts, and carbon handlebars are vulnerable to strong force applied to a single point, so there is a high possibility of cracks in them if they are tightened with more than the torque specified by the manufacturer.

This is why it is said that “torque management is essential when using carbon parts.

Although torque wrenches have many advantages, they also have disadvantages.

First, the wrench itself is expensive. While you can get a high-quality set of common Allen keys for as little as $30, most torque wrenches cost around $100. Even if it is for your precious bike, you may hesitate to pay $100 for a tool that you do not use often.

Another disadvantage of torque wrenches is that there is a possibility that the measured value will shift with continued use, or that the torque value may not be accurate depending on the manufacturer.

If the torque value becomes misaligned, it is possible to overtighten and crack the wrench if it is tightened as specified by the torque wrench, so it can be said that there are unexpected risks lurking.

Torque wrenches can become misaligned with frequent use, and low-quality torque wrenches may not give the correct value when you buy them. For this reason, professional stores usually install torque wrenches from manufacturers who are sure of their quality, and after a certain period of use, leave the wrenches with the manufacturer to have the torque corrected. In other words, torque wrenches require “servicing the wrench itself”.

Sponsored Link

Road Bike Maintenance for Beginners at Home

We have compiled a list of road bike maintenance that even beginners can start with tools they have at home. The menu emphasizes maintaining road bike performance and early detection of problems.

Summary of tools needed to replace sprockets

Replacing sprockets is an affordable upgrade, such as upgrading gears or customizing gear ratio changes. We have compiled a list of tools needed for sprocket replacement.

Essential Special Tools for Installing and Servicing Shimano Hollowtech 2

Hollowtech 2" is the standard adopted by the latest Shimano front cranks. We have compiled a list of special tools required for installation and maintenance of "Hollowtech 2", which is unavoidable when upgrading to higher grade front cranks.

Bicycle Tool Sets: Pros, Cons, and Buying Guide

A "bicycle tool set" is a set of tools necessary for bicycle maintenance and is reasonably priced. The following is a summary of the advantages and disadvantages of buying a bicycle tool set and points to keep in mind when buying one.

Hex Wrench Sizes for Road Bike Maintenance

For those who will be servicing their road bikes, we have compiled a list of hex wrench sizes that are commonly used for road bike maintenance and that you should have available.

Torque Wrench: Advantages and Disadvantages of Torque Management

A torque wrench is a useful tool to have if you want to properly maintain your road bike or MTB. The following is a summary of what a torque wrench is and the advantages and disadvantages of torque management.

Road Bike Maintenance for Beginners at Home

We have compiled a list of road bike maintenance that even beginners can start with tools they have at home. The menu emphasizes maintaining road bike performance and early detection of problems.

Hex Wrench Sizes for Road Bike Maintenance

For those who will be servicing their road bikes, we have compiled a list of hex wrench sizes that are commonly used for road bike maintenance and that you should have available.

Bicycle Tool Sets: Pros, Cons, and Buying Guide

A "bicycle tool set" is a set of tools necessary for bicycle maintenance and is reasonably priced. The following is a summary of the advantages and disadvantages of buying a bicycle tool set and points to keep in mind when buying one.

Summary of tools needed to replace sprockets

Replacing sprockets is an affordable upgrade, such as upgrading gears or customizing gear ratio changes. We have compiled a list of tools needed for sprocket replacement.

Essential Special Tools for Installing and Servicing Shimano Hollowtech 2

Hollowtech 2" is the standard adopted by the latest Shimano front cranks. We have compiled a list of special tools required for installation and maintenance of "Hollowtech 2", which is unavoidable when upgrading to higher grade front cranks.

It is surprisingly difficult to remember where to do bicycle greasing. In this article, we summarize the role of bicycle grease and how and where to use it.

Wire Types and Differences for Road Bikes, MTB, and Hybrid Bikes

This is a summary of the types and differences of wires for MTB and hybrid bikes for road bikes. The interchangeability of each, and how the wires affect your riding.

How to choose and inflate a road bike inflator

Managing air pressure on a road bike is known as "the basics." We have compiled a list of how to select and inflate air pressure for road bicycles, which is similar to but slightly different from that of city bicycles.

Shimano Chain Compatibility for Road, MTB, and Hybrid Bikes

An overview of Shimano chain compatibility across road bikes, mountain bikes, and hybrid bikes. Includes guidance on how to choose the right chain for your drivetrain.

Shimano ESSA Lineup and Compatibility with Existing 8-Speed Parts

An overview of Shimano's newly released 8-speed component group "ESSA" and its compatibility with existing 8-speed parts.

Compatibility Guide for SRAM MTB Components

A detailed explanation of compatibility between SRAM MTB components. This guide outlines which parts can be used together and which combinations are not compatible.

Shimano Hydraulic Brake Hose and Connector Standards Guide

An explanation of the differences between Shimano’s hydraulic brake hoses BH90 and BH59, the types of connecting bolts, and how to choose the right hose for your brake system—including key points to watch out for.

In-Depth Guide to Shimano 12-Speed Cassette Compatibility

A detailed explanation of the key compatibility factors when using Shimano's 12-speed cassettes—specifically the required wheel (freehub) and drivetrain, which differ significantly from previous 11-speed systems.

Perfect Guide to Shimano 11-Speed Cassette Compatibility

A detailed explanation of two key compatibility factors when using Shimano 11-speed cassettes: the required wheel (freehub) and drivetrain.

Perfect Guide to Shimano 10-Speed Cassette Compatibility

A detailed explanation of two key compatibility factors when using Shimano 10-speed cassettes: the required wheel (freehub) and drivetrain.

In-Depth Guide to Shimano 9-Speed Cassette Compatibility

A comprehensive explanation of two key compatibility factors when using Shimano 9-speed cassettes: the required wheel (freehub) and drivetrain.

Shimano CUES Components Lineup and Compatibility Guide

A comprehensive guide to Shimano's new CUES component group for MTB and lifestyle categories, including gear ratios, part lineup, and compatibility with traditional components.

TPU Inner Tube: Features, Pros, and Cons for Road Bikes and MTB

TPU inner tubes are gaining attention as the third force in bicycle tires. We summarize its features, advantages and disadvantages of using it on Road bikes and MTBs, and major manufacturers.

Shimano Mechanical Brake Levers for MTB and Hybrid Bike

Shimano mechanical brake levers are now few and far between. The following is a summary of the current model lineup, specifications, and compatible components.

Differences Between 700C Road Wheels and 29er MTB Wheels

A comparison of the similarities and differences between 700C road bike wheels and 29er MTB wheels, including key points on how to choose and the considerations when switching between these types of wheels.

Summary of electric components for MTB

This section summarizes the types of electric components for MTB and the advantages and disadvantages of each.

MTB Dropper Seatposts: Types and Considerations

The dropper seat post is becoming a "must-have" part for MTB. Here we summarize the lineup, specifications, and features of dropper seatposts for MTB from major manufacturers, as well as a comparison of each manufacturer and points to consider when choosing a dropper seatpost.

Freehub Types, Standards, and Compatibility for Road and MTB Wheels

A summary of the different types and standards of freehubs used in road and MTB wheels, along with their compatibility with various cassettes.

SRAM Component Grades and Compatibility Summary for MTB

This section summarizes the grades, features, and compatibility of SRAM's Eagle series of components for MTB, as well as the electric component AXS and the latest component, Eagle Transmission.

Choosing SRAM MTB Sprockets: Compatibility and Key Considerations

SRAM components are being increasingly adopted in entry-grade MTB. In this issue, we summarize SRAM's sprockets for MTB and points to consider when choosing one.

12-speed sprockets for MTB compatible with Shimano Free Hub(HG spline)

We have put together a 12-speed sprocket that is not part of Shimano's 12-speed lineup for MTB. With this one, it is possible to convert to 12-speed with a conventional Shimano Free Hub (HG spline) without upgrading the wheels.

MTB suspension fork interchangeability standard! You definitely want to check when replacing.

When it comes to serious MTB customization, suspension fork upgrades are the way to go. However, there are various standards for MTB suspension forks, and if you choose the wrong one, it may not work at all.

Shimano MTB sprocket and wheel compatibility summary

This section summarizes the compatibility of Shimano's sprockets and wheels (free bodies) for MTB, which are a mixture of old and new standards, the latest Micro Spline and the previous HG spline, and what to look out for when purchasing.